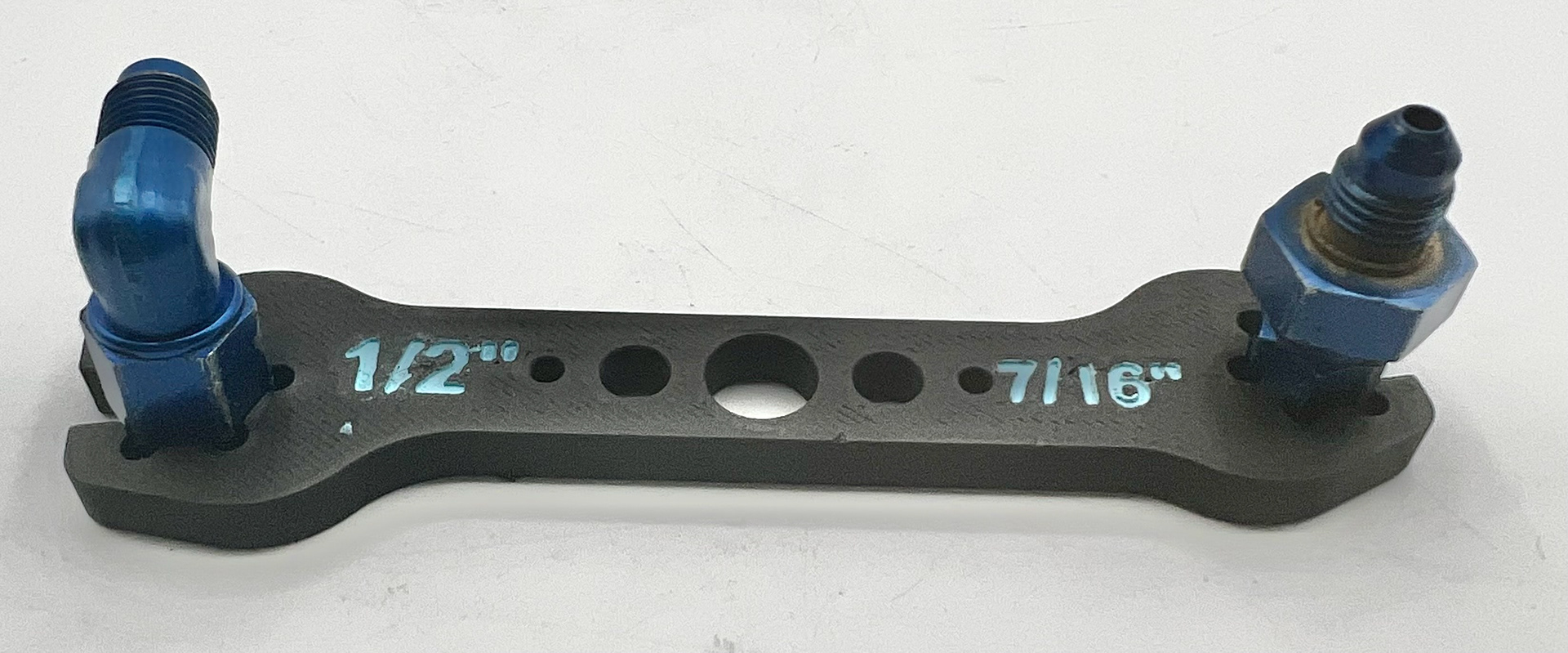

I started this project because I wanted a doubled-ended AN wrench for use in brake lines for Rensselaer Motorsport's RM25, which uses almost exclusively AN-3 fittings. Specifically, I wanted a double-ended AN-3 wrench, because every AN size is actually two sizes (socket and nut.) But double-ended AN wrenches usually only come in full sets, which can easily cost over $100! Which is why I decided to design my own and 3D print it.

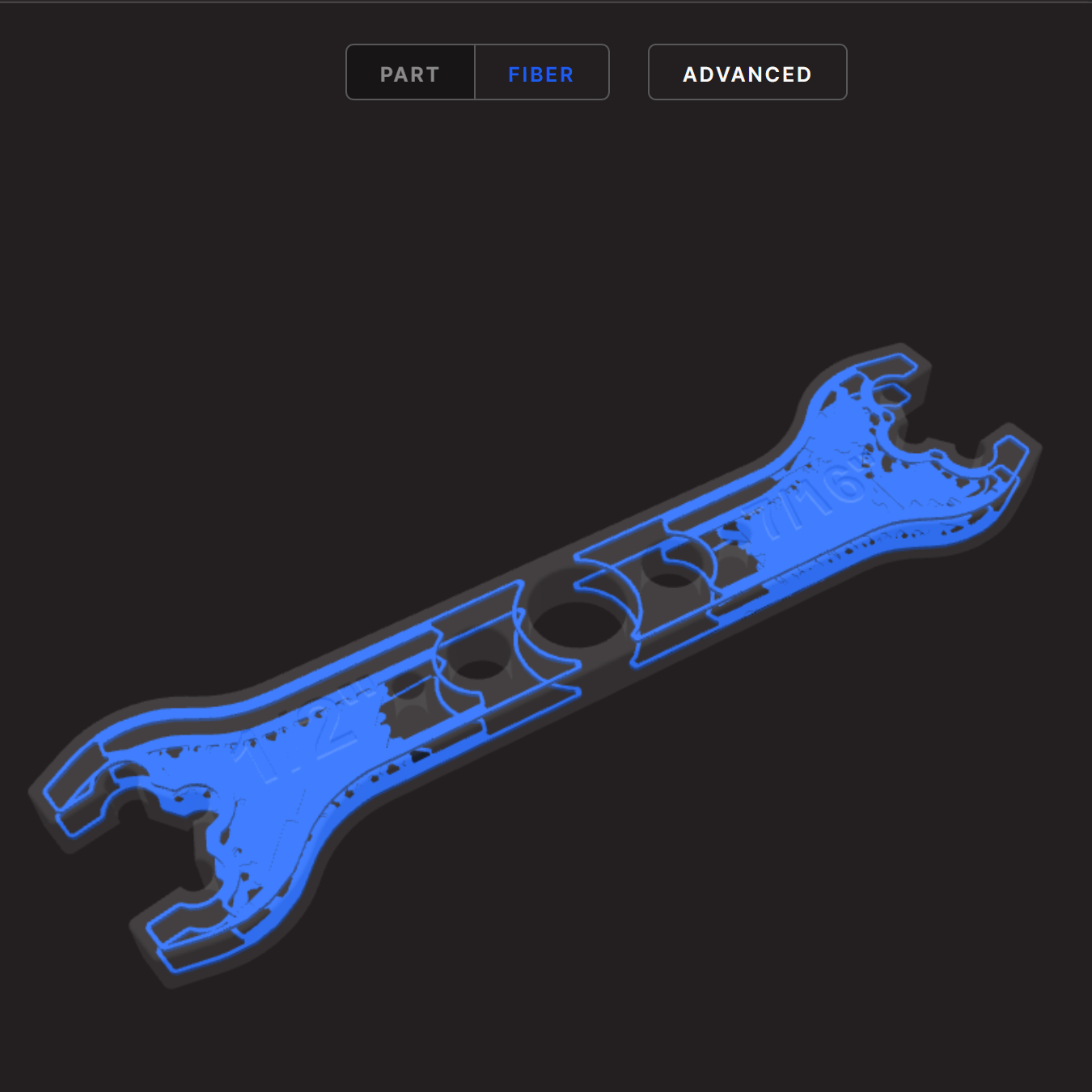

Commercial AN wrenches are made of billet aluminum, so they don’t deform the anodized aluminum fittings used to connect fluid-carrying hoses and tubes in vehicles. I decided to make mine out of Markforged’s Onyx (a chopped carbon-infused Nylon), because it is both strong enough for the application but soft enough not to scratch the fittings. Then to add extra rigidity, I reinforced the design with continuous carbon fiber. Because AN fittings should only be hand-tight, the design didn't have to withstand a particularly high torque load.

I also had the idea to create a line-wrench version of my design, to help the wrench stay on the fitting in awkward spaces.

The final designs were printed on a Markforged Mark 2, and the size labels were marked with acrylic paint pens. I debated between marking them with their AN-size or the fractional size, and in the future will probably update the design to include both.

Note, the AN fittings in the photos are scratched-up because they were previously disassembled using a steel wrench. They weren't scratched by this 3D-printed one I made!