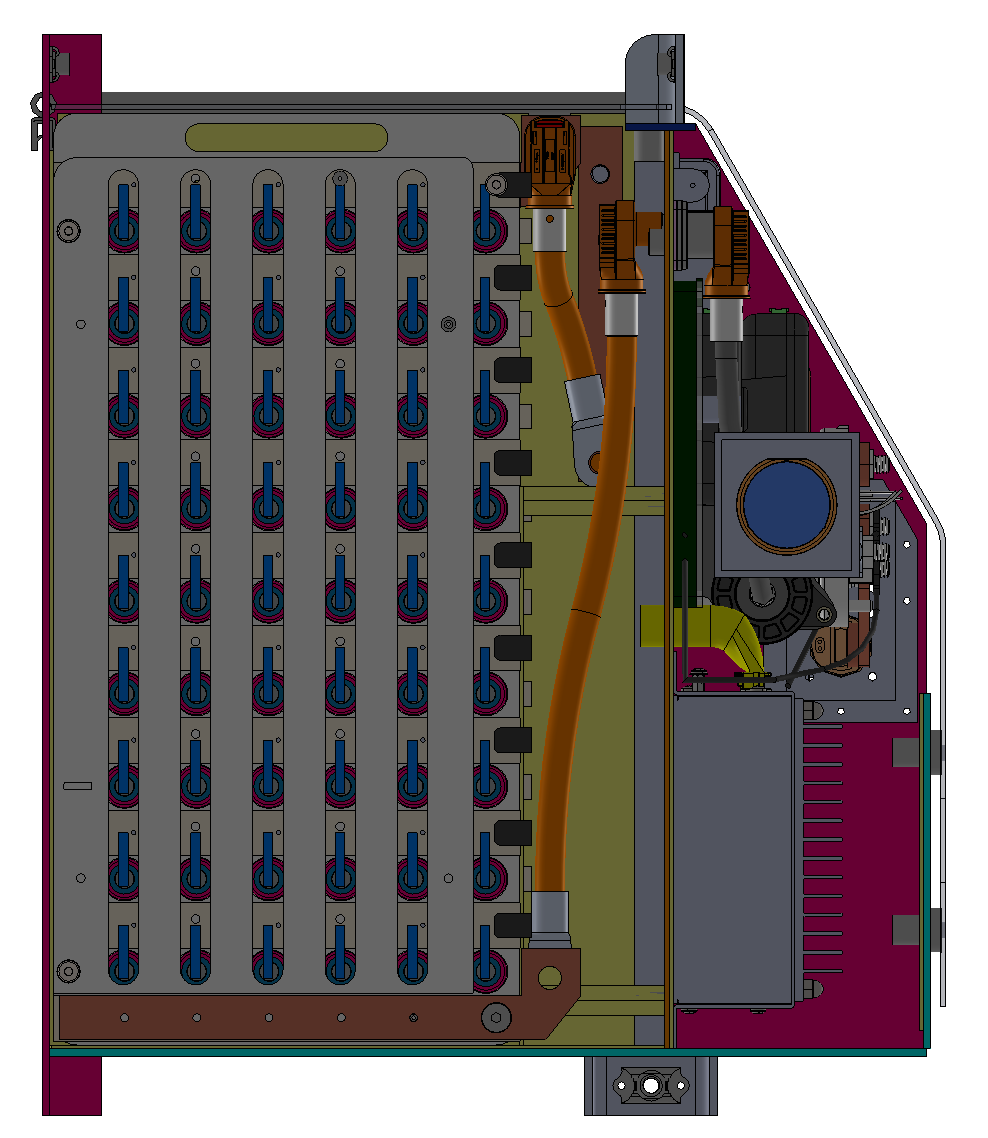

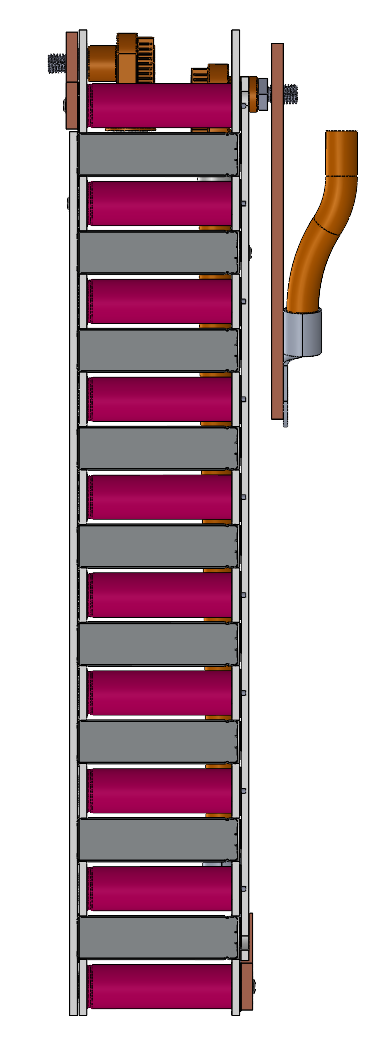

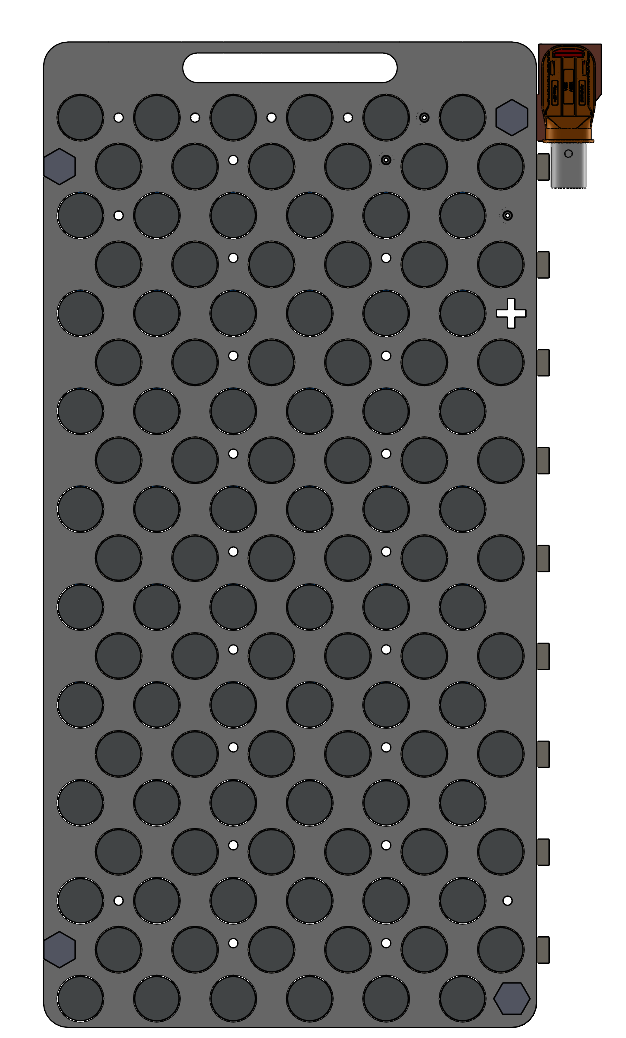

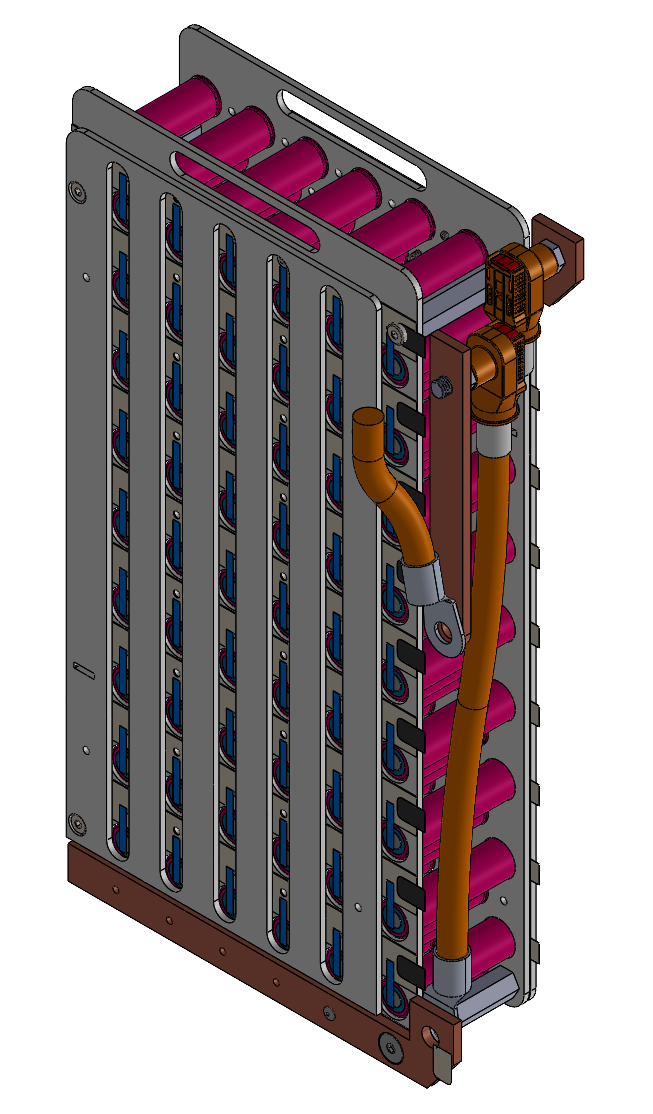

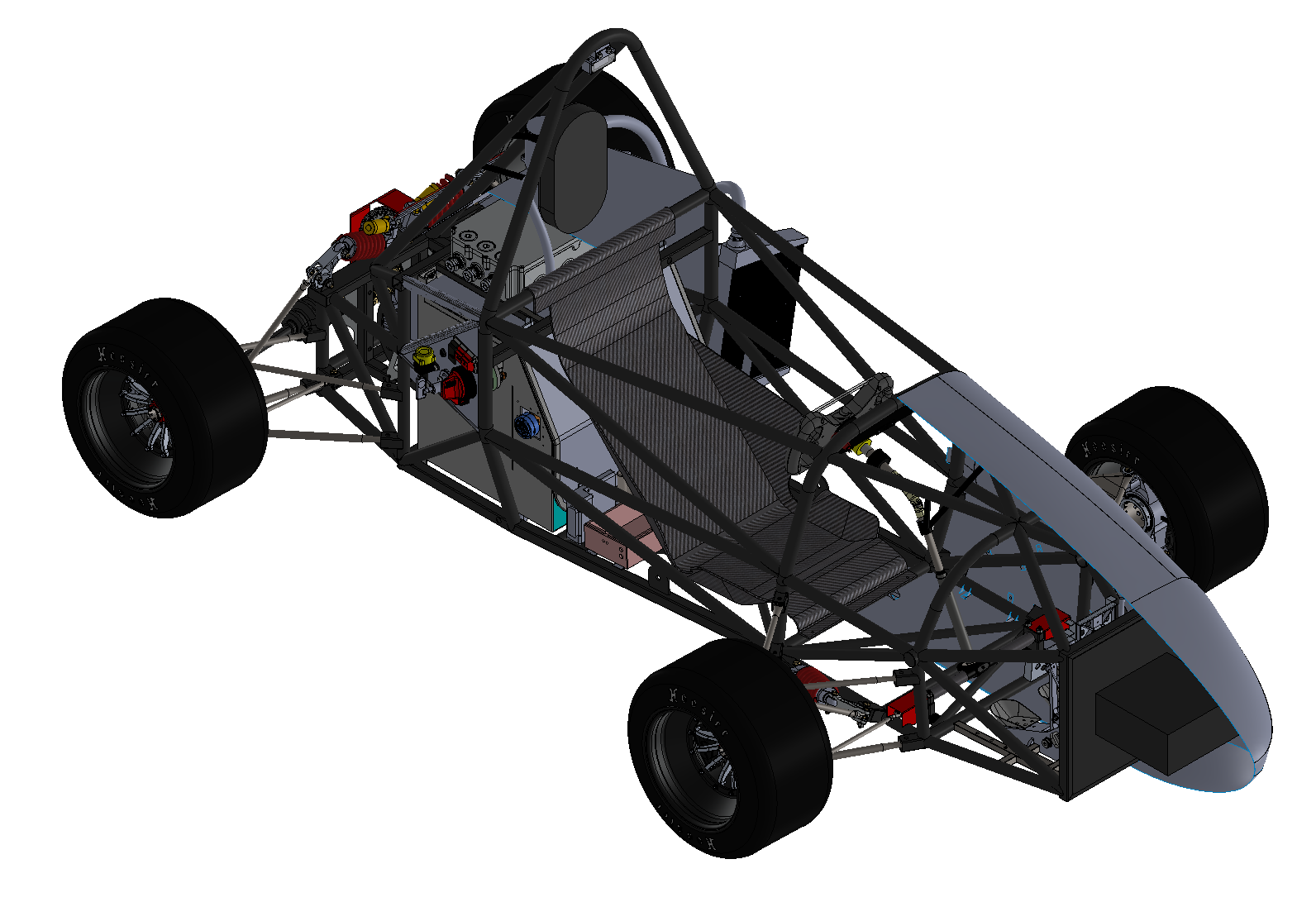

1800 parts

90 unique

Preliminary Design Review Slide Deck

Critical Design Review Slide Deck

Design Process Hilights

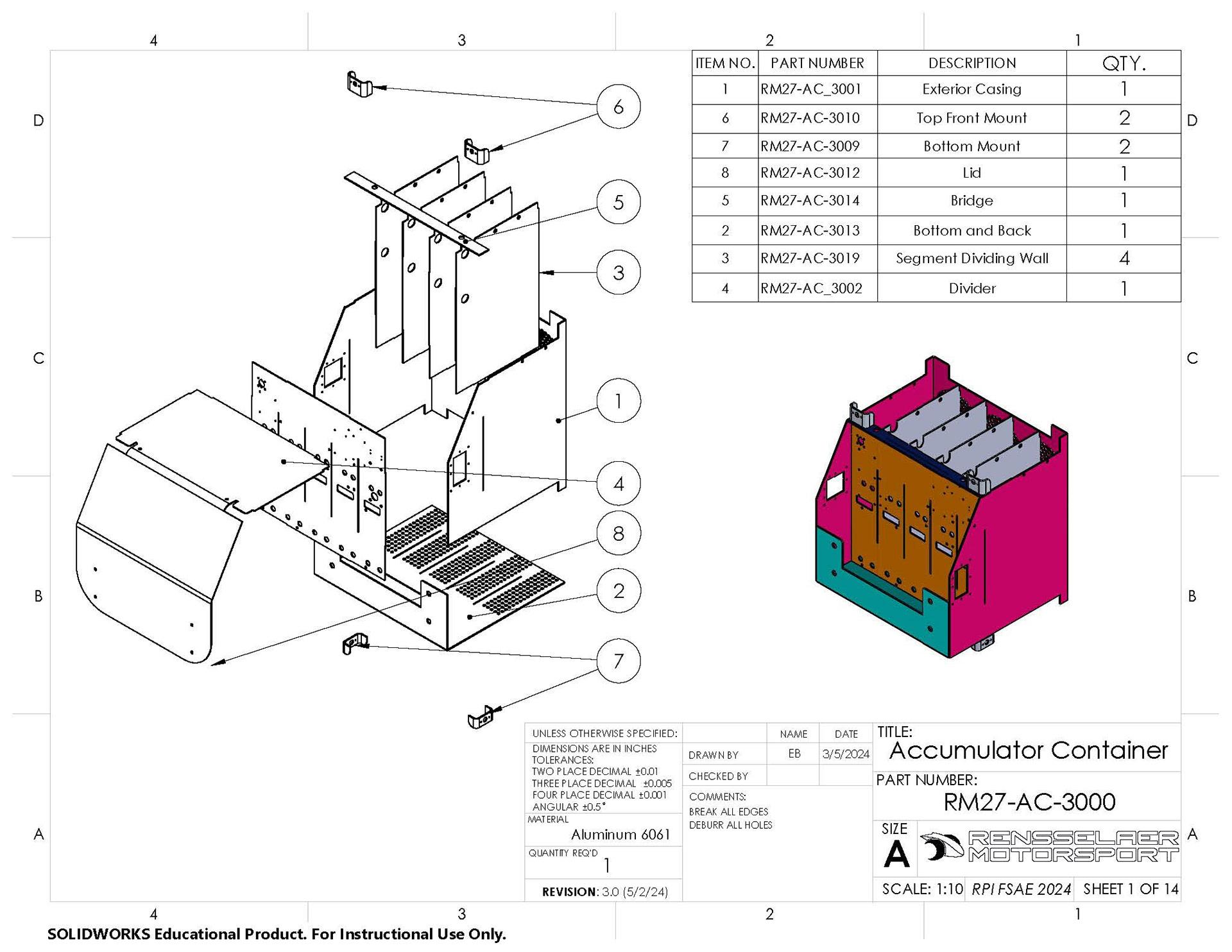

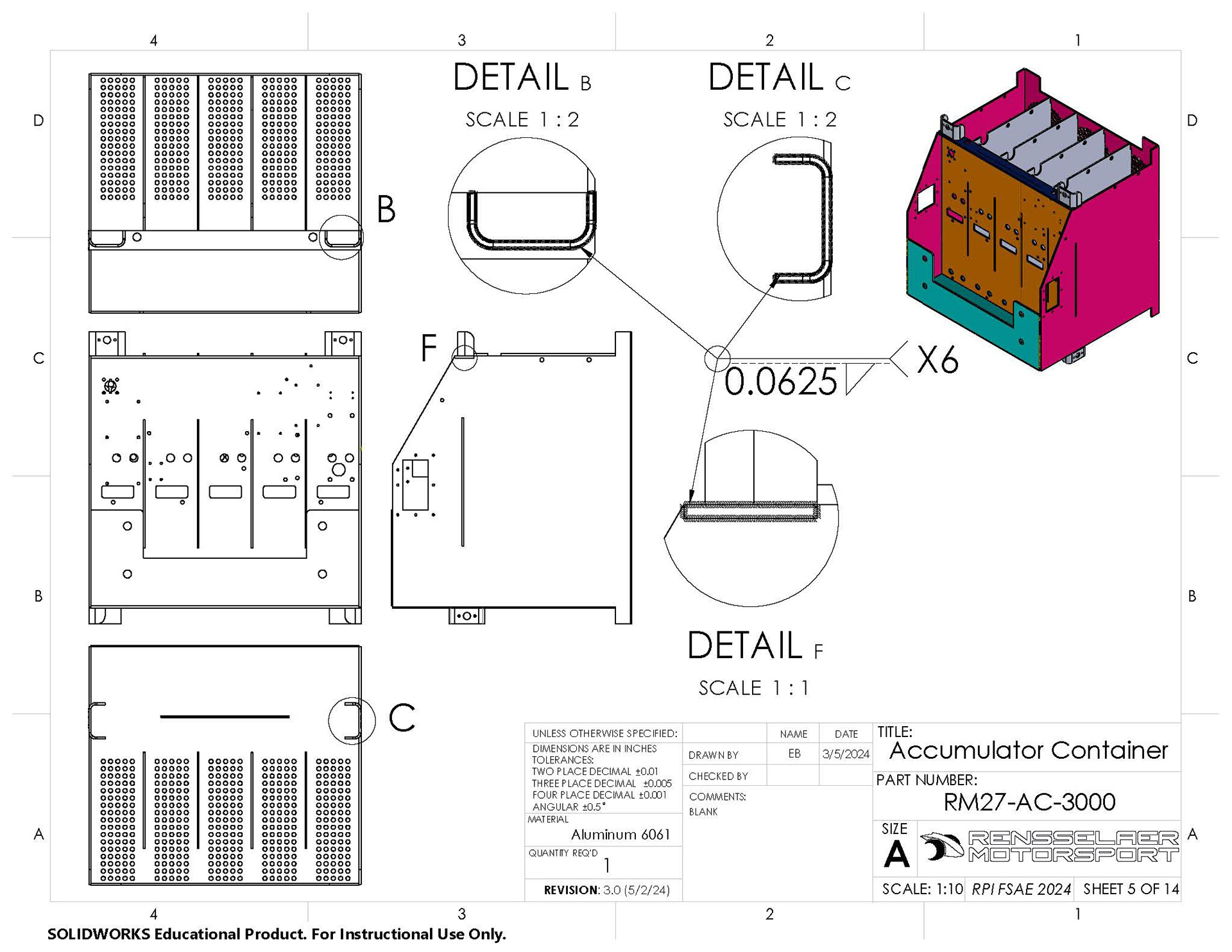

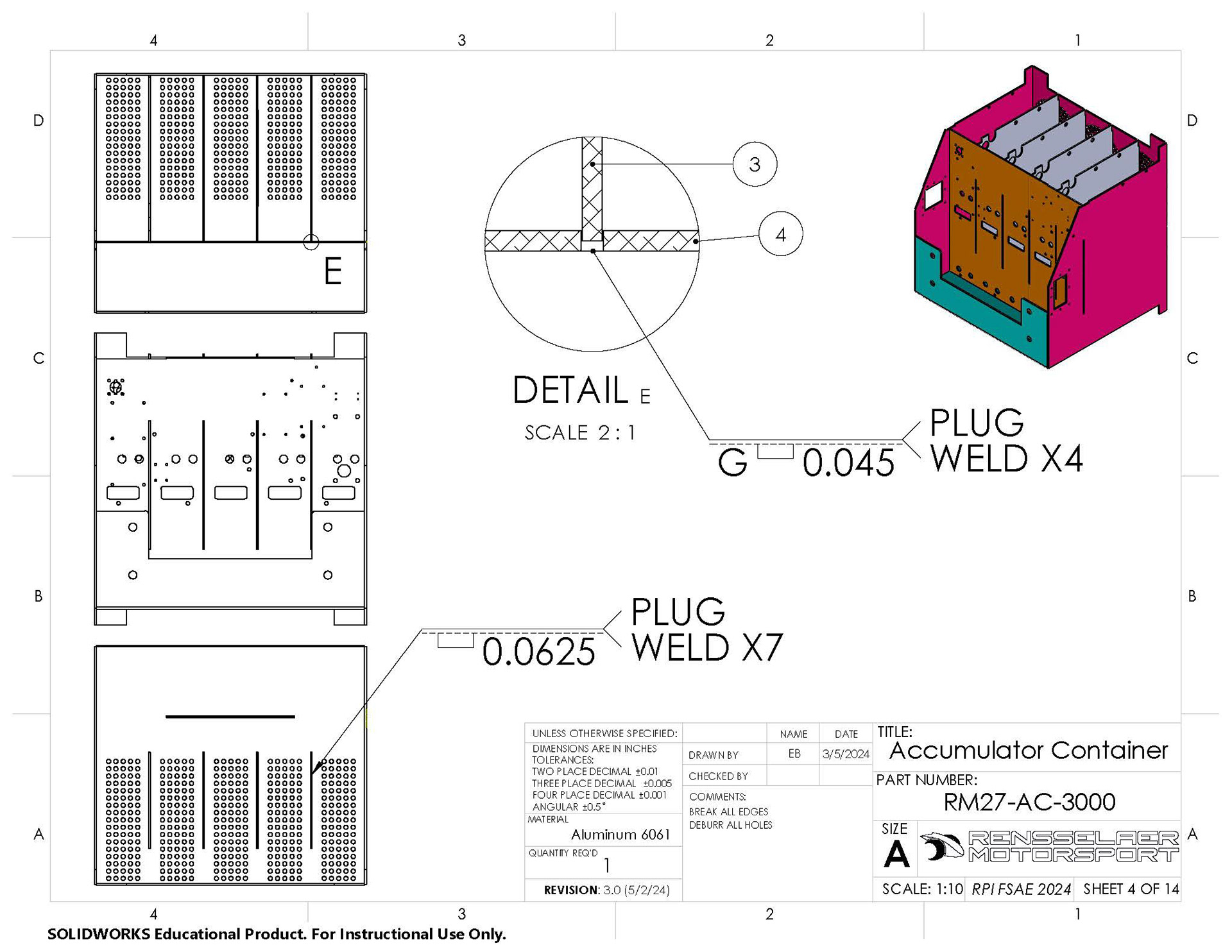

Final Design

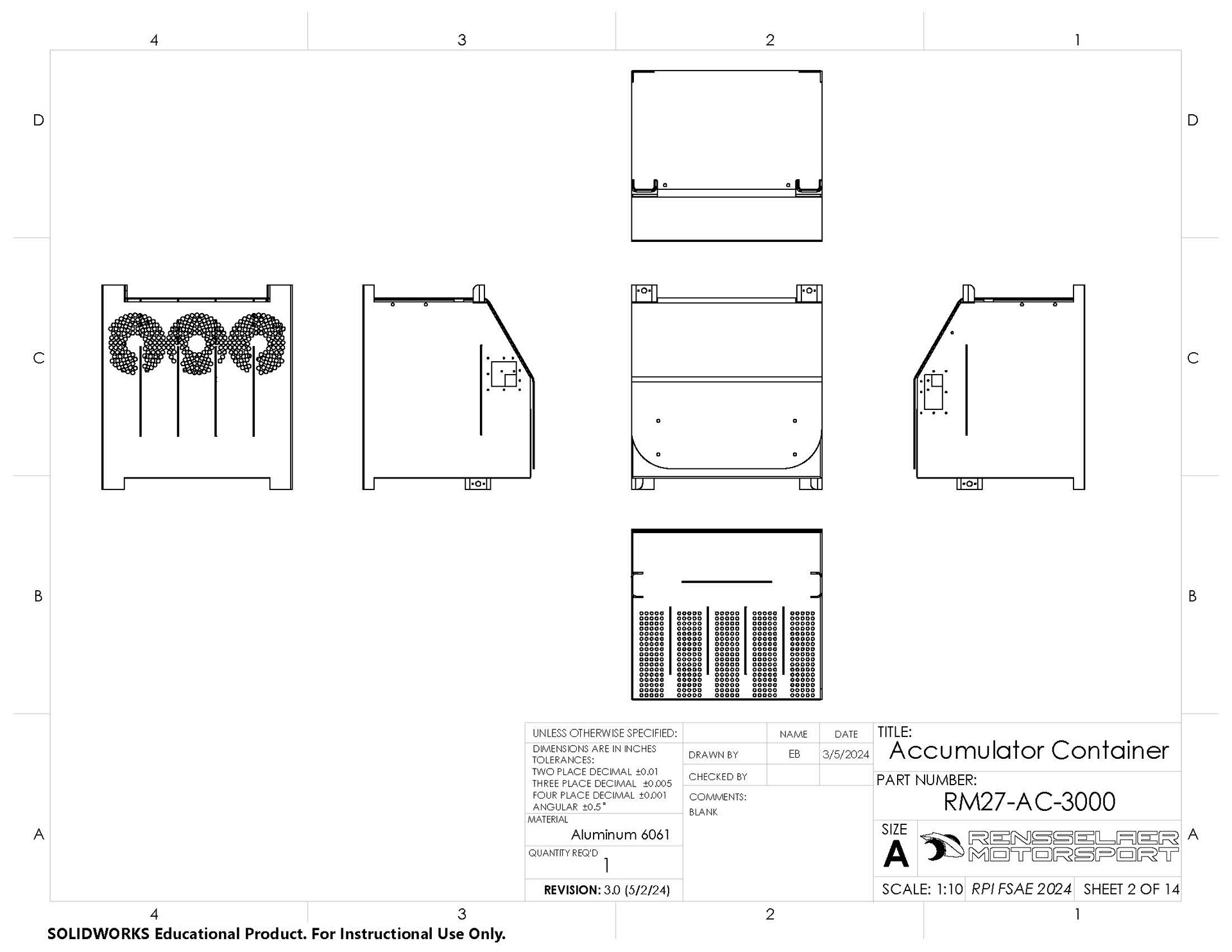

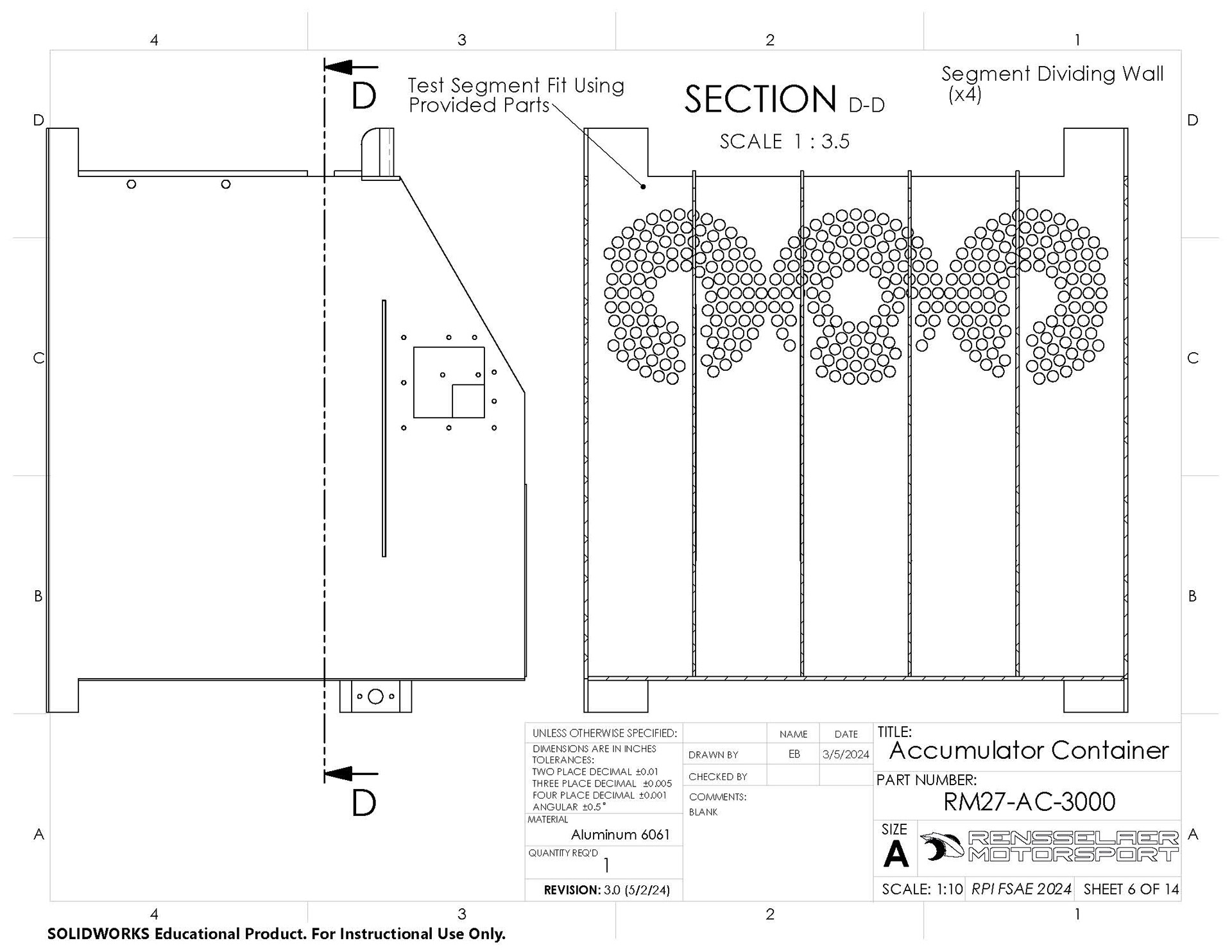

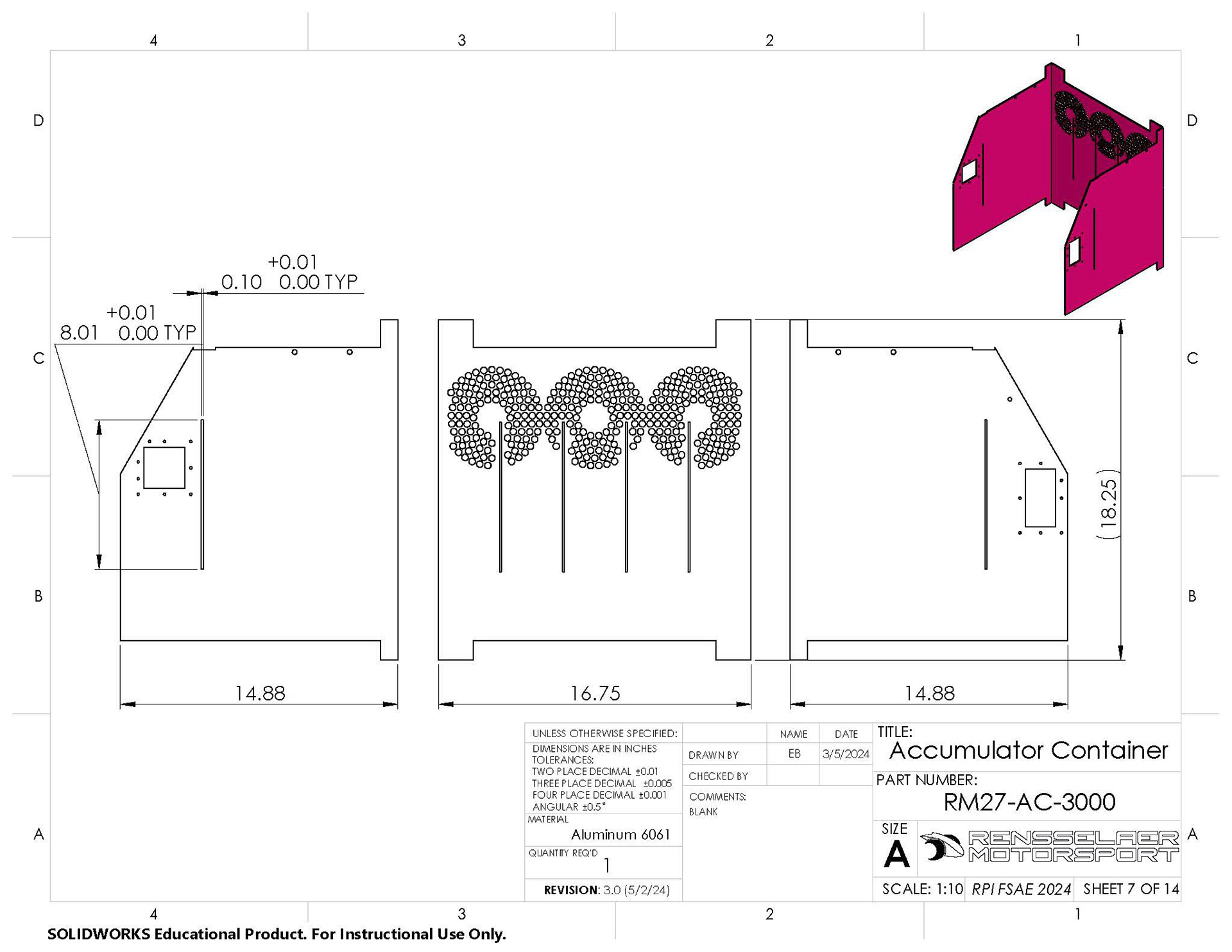

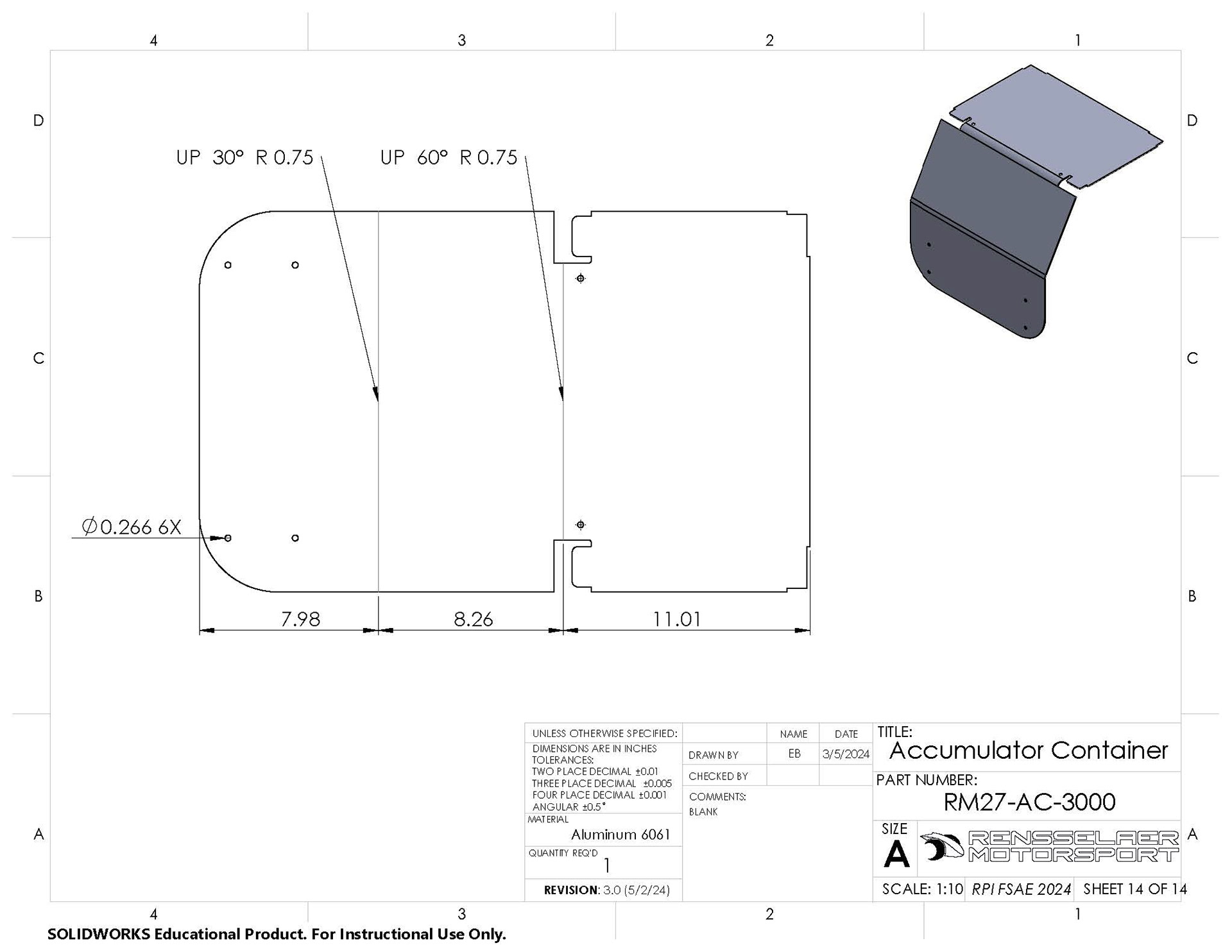

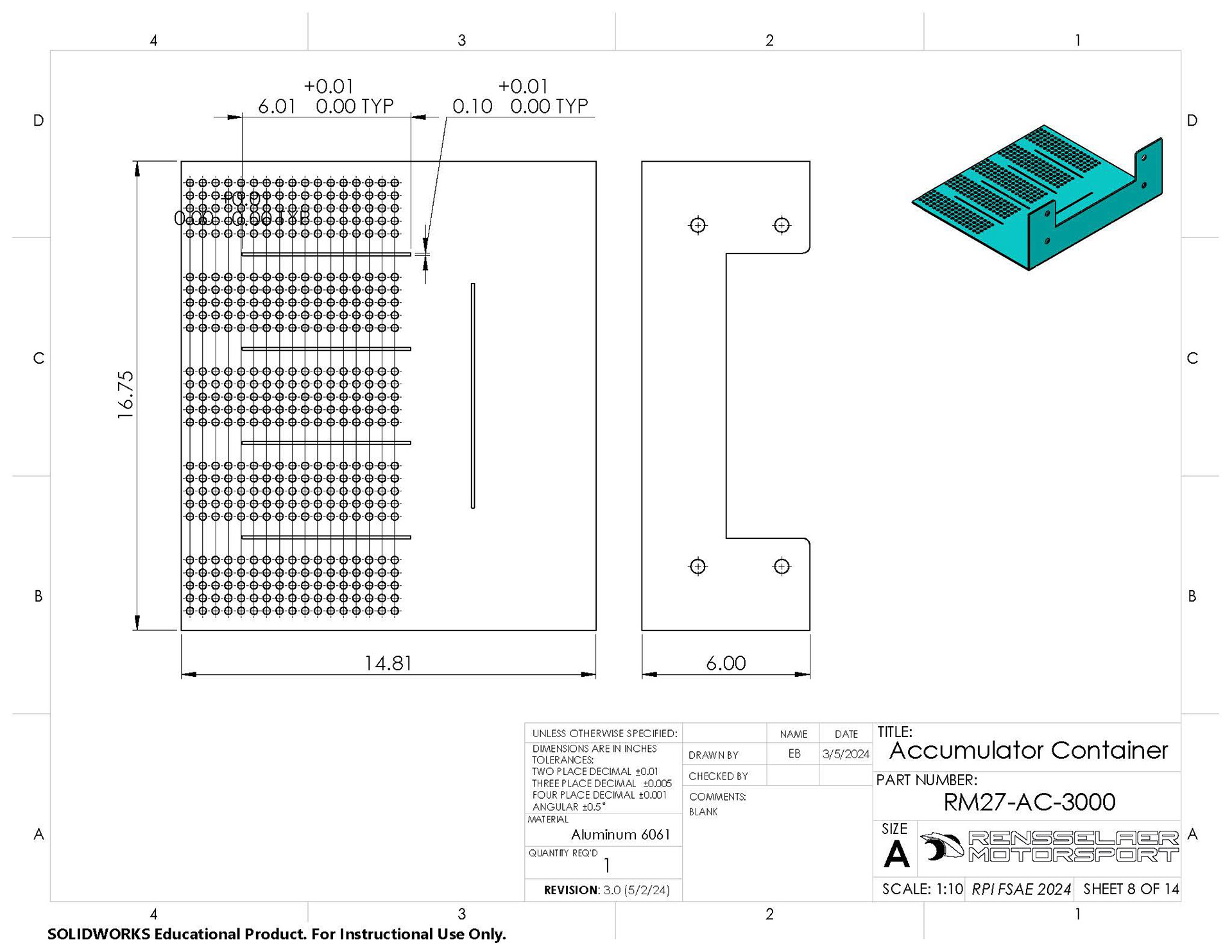

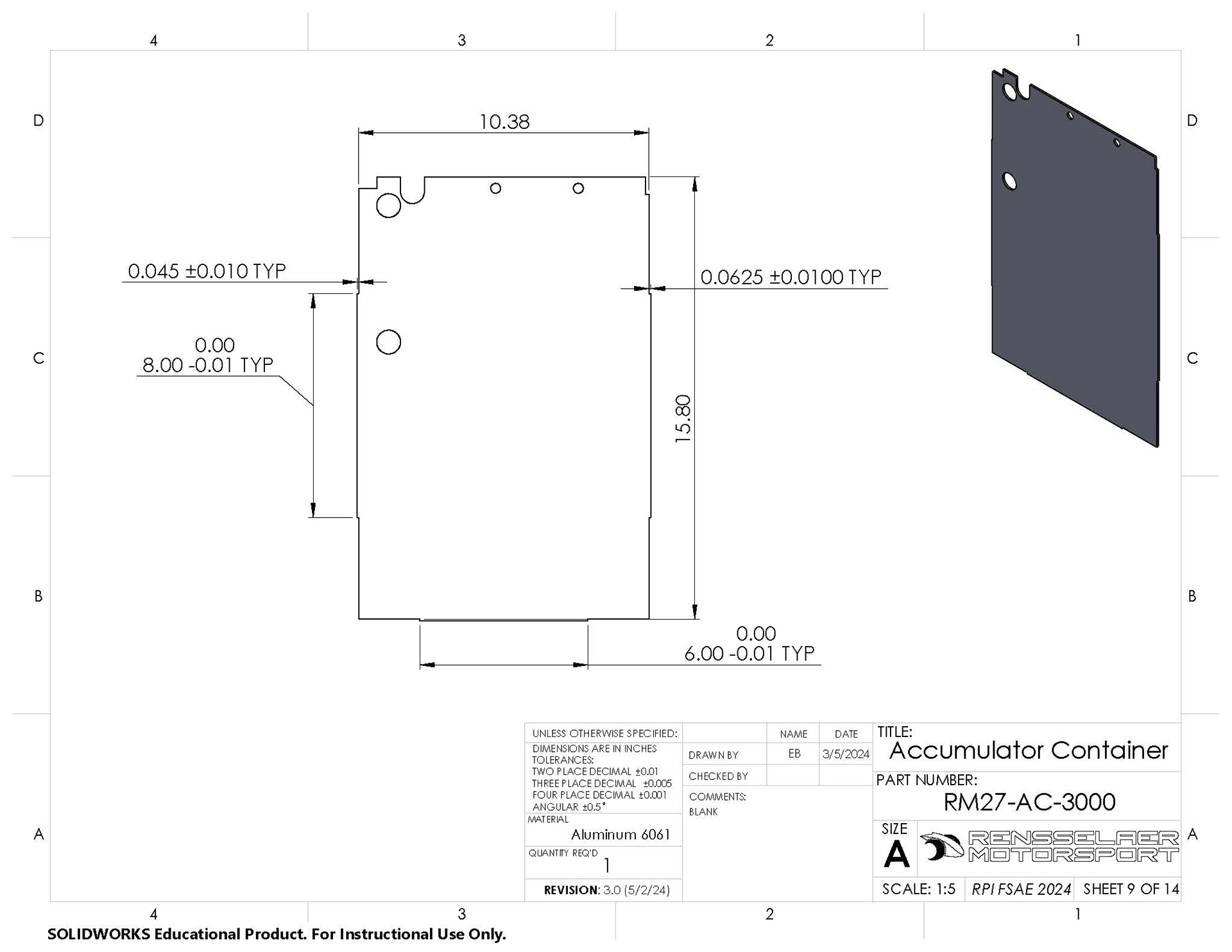

Final Drawings (Highlights)

as sent to the manufacturer, drawings by Erich Bahm

full drawings available here

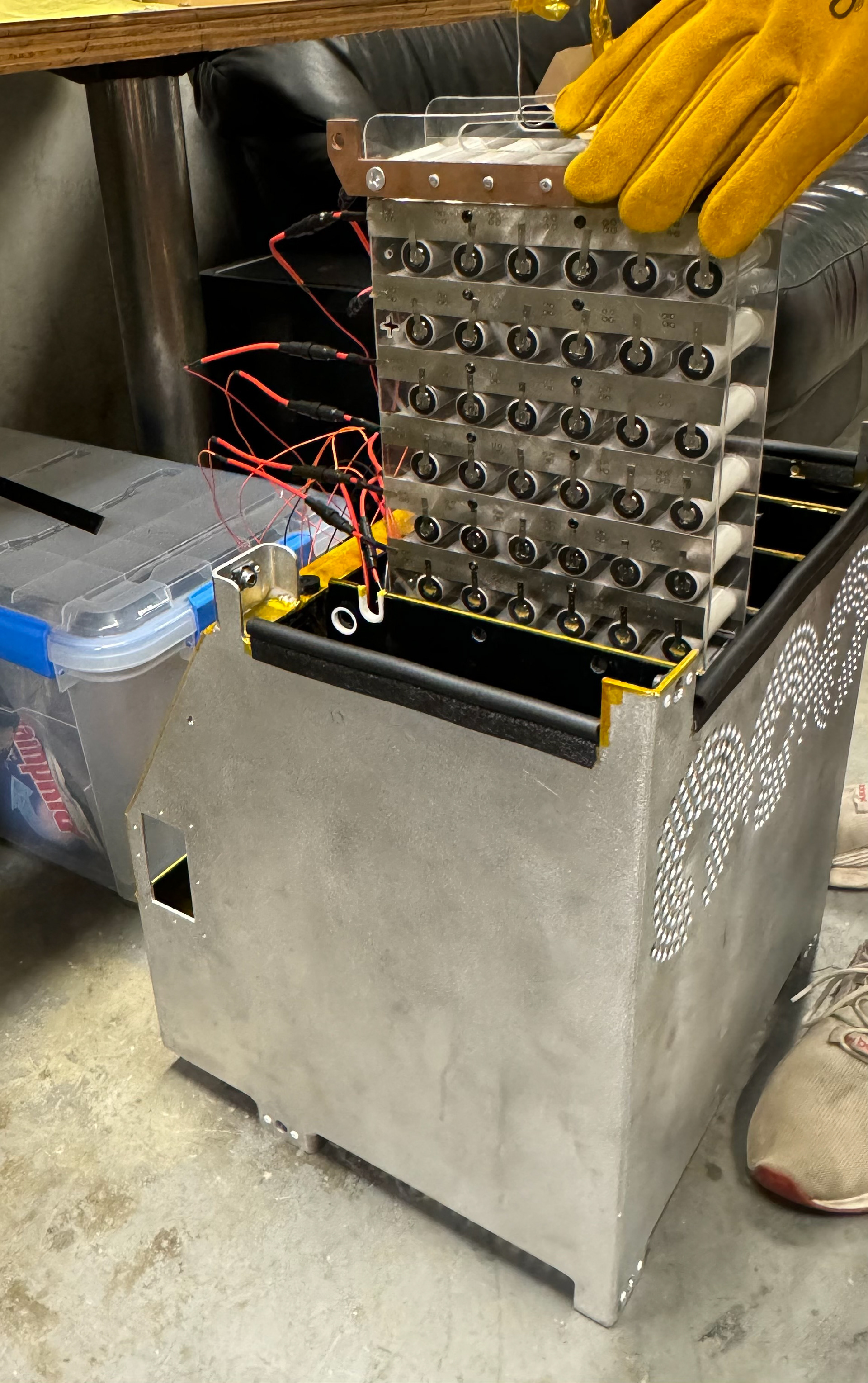

Container Manufacturing Pictures

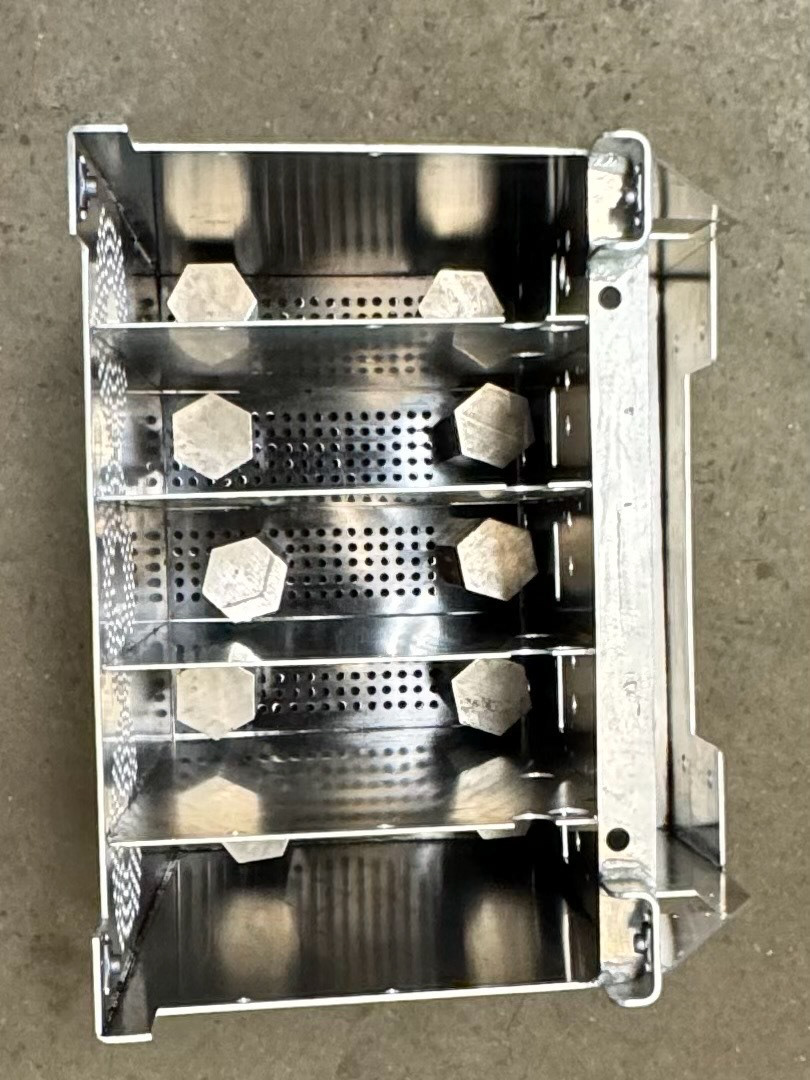

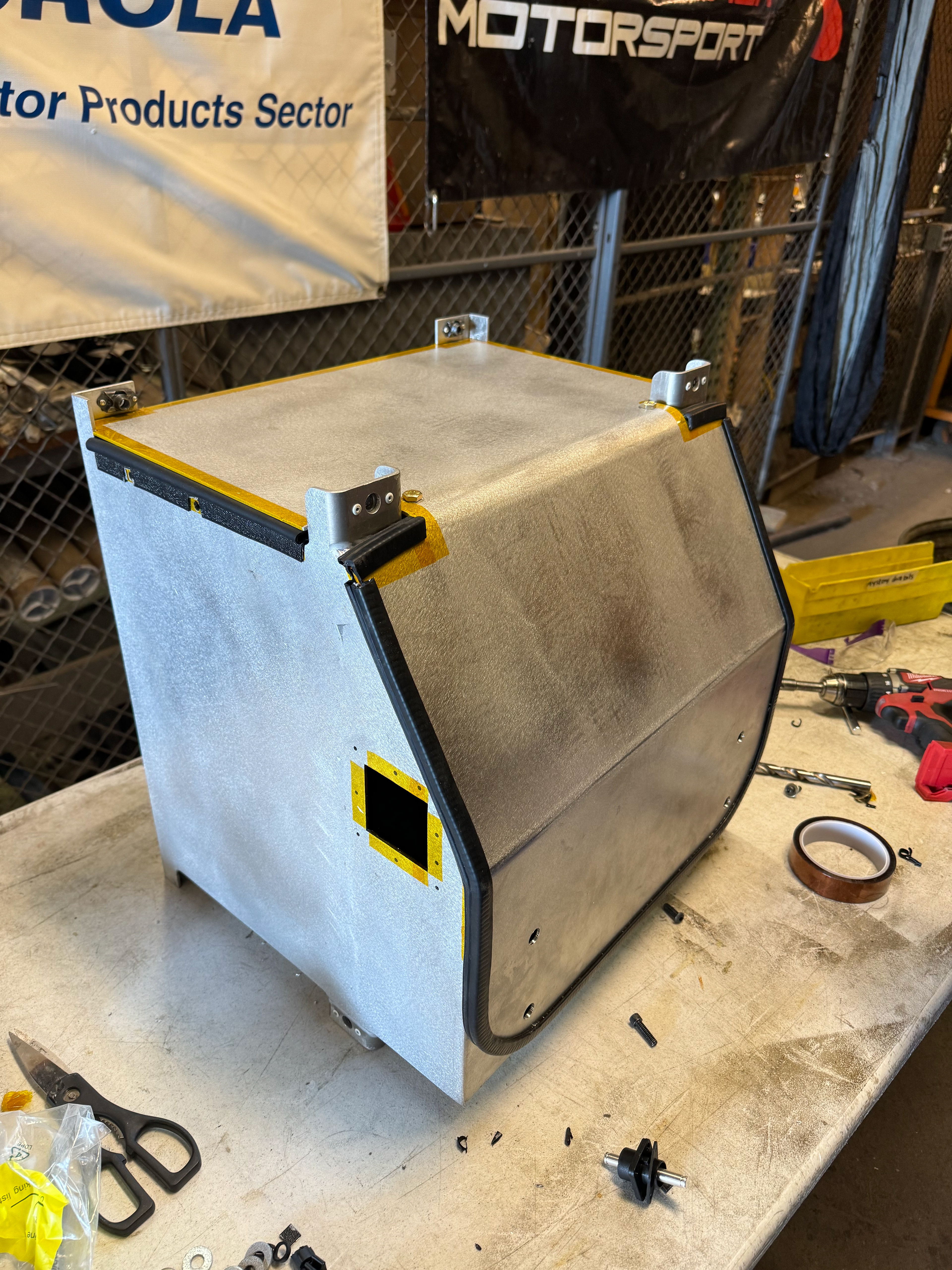

finished sheet metal box as picked up from manufacturer

transporting the container back from the manufacturer

test fitting in the chassis for the first time

the front of the container after grinding welds flush

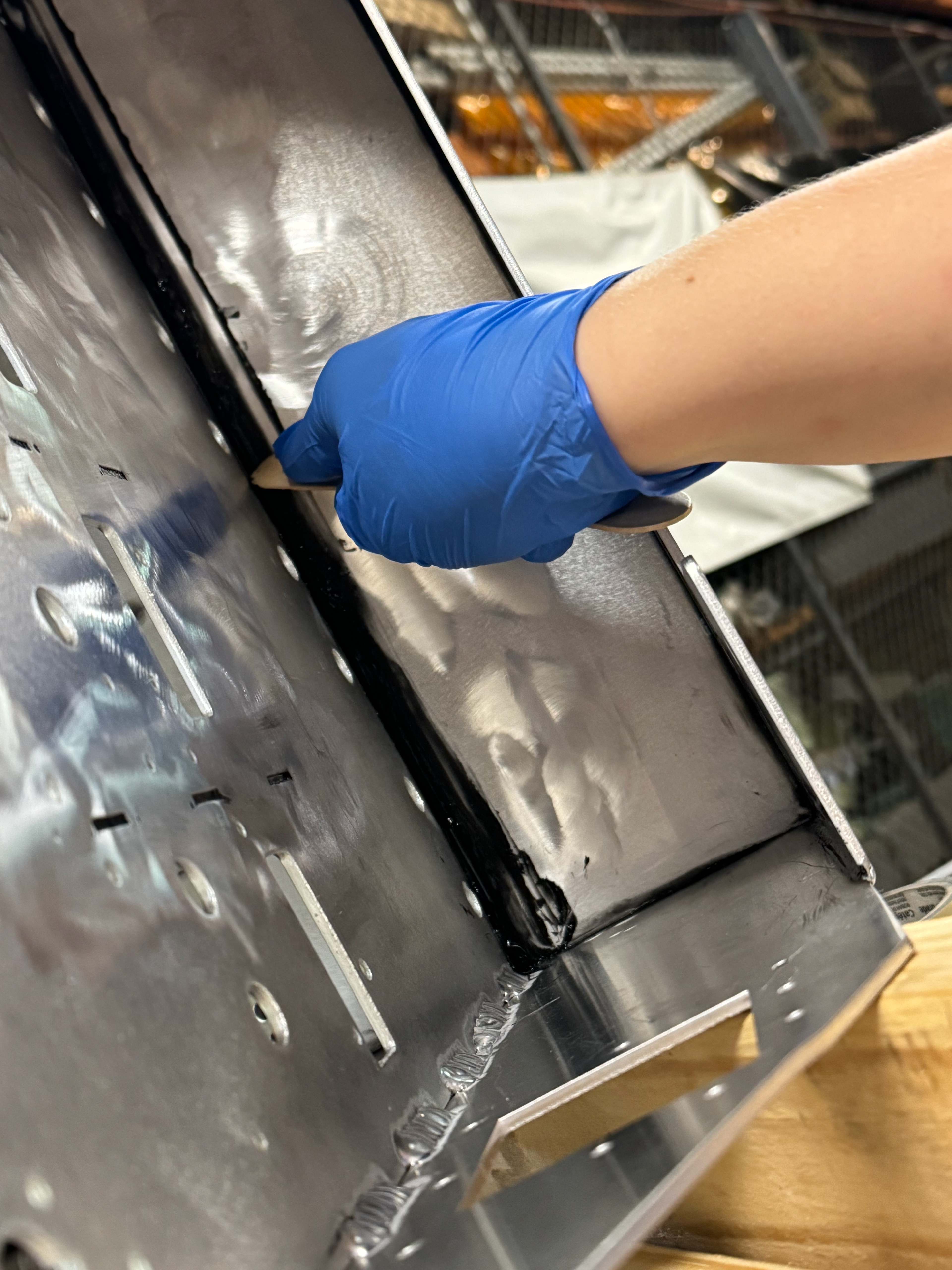

sealing the joins with RTV

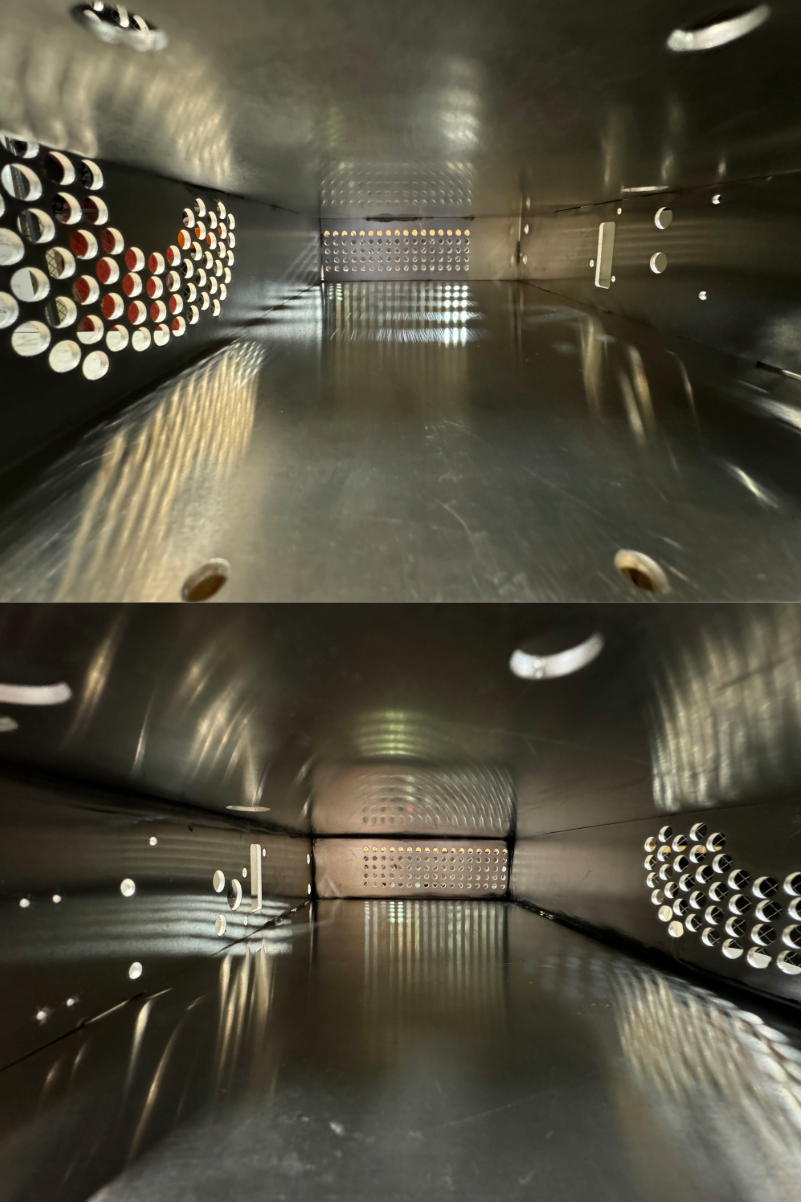

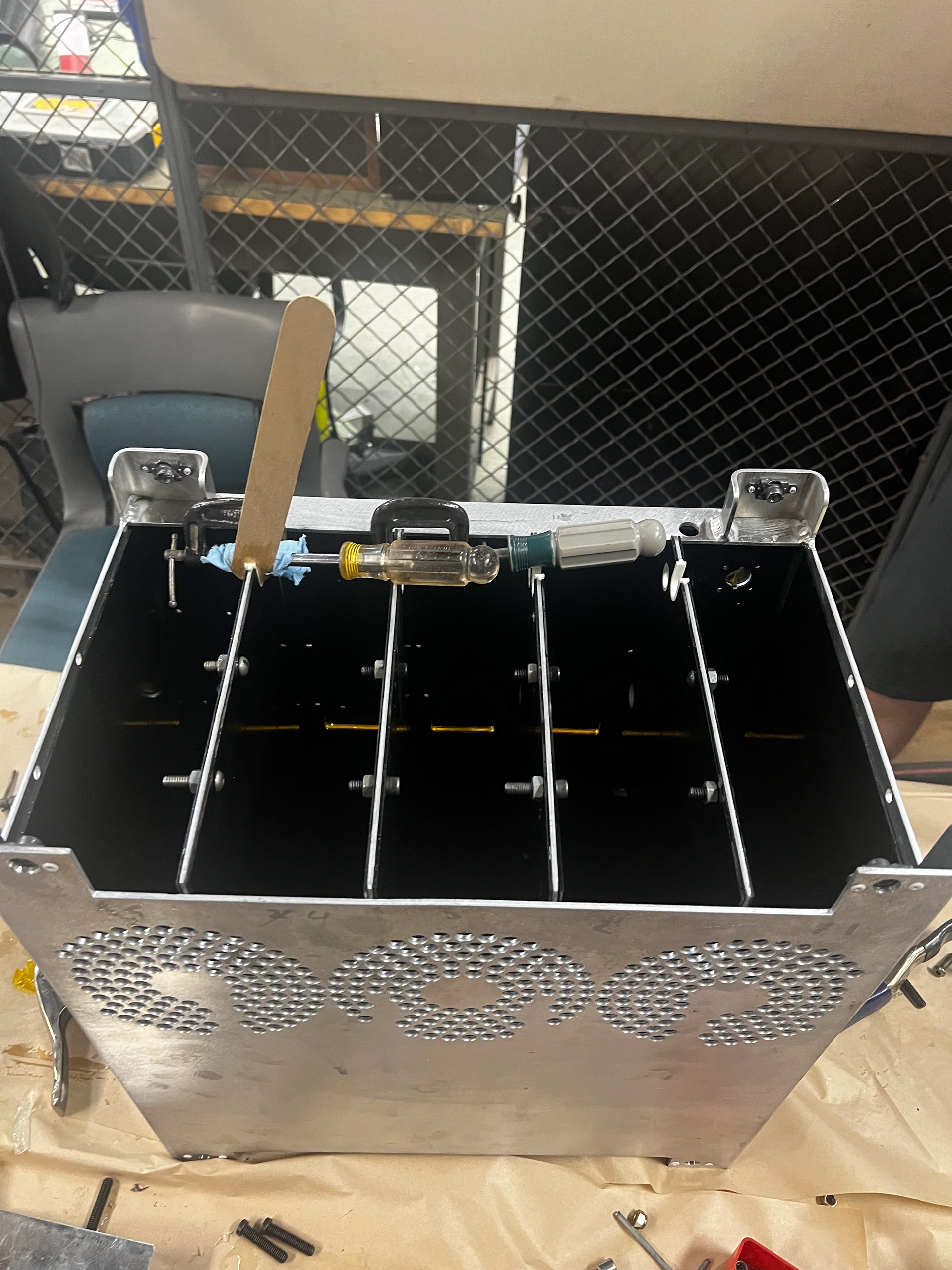

the inside of a segment bay before and after sealing seams

test fitting G10 insulation pieces

sanding station for G10

sanding the G10 pieces to fit with proper PPE

setting up glueing station

applying an even expocy coat to G10 pieces

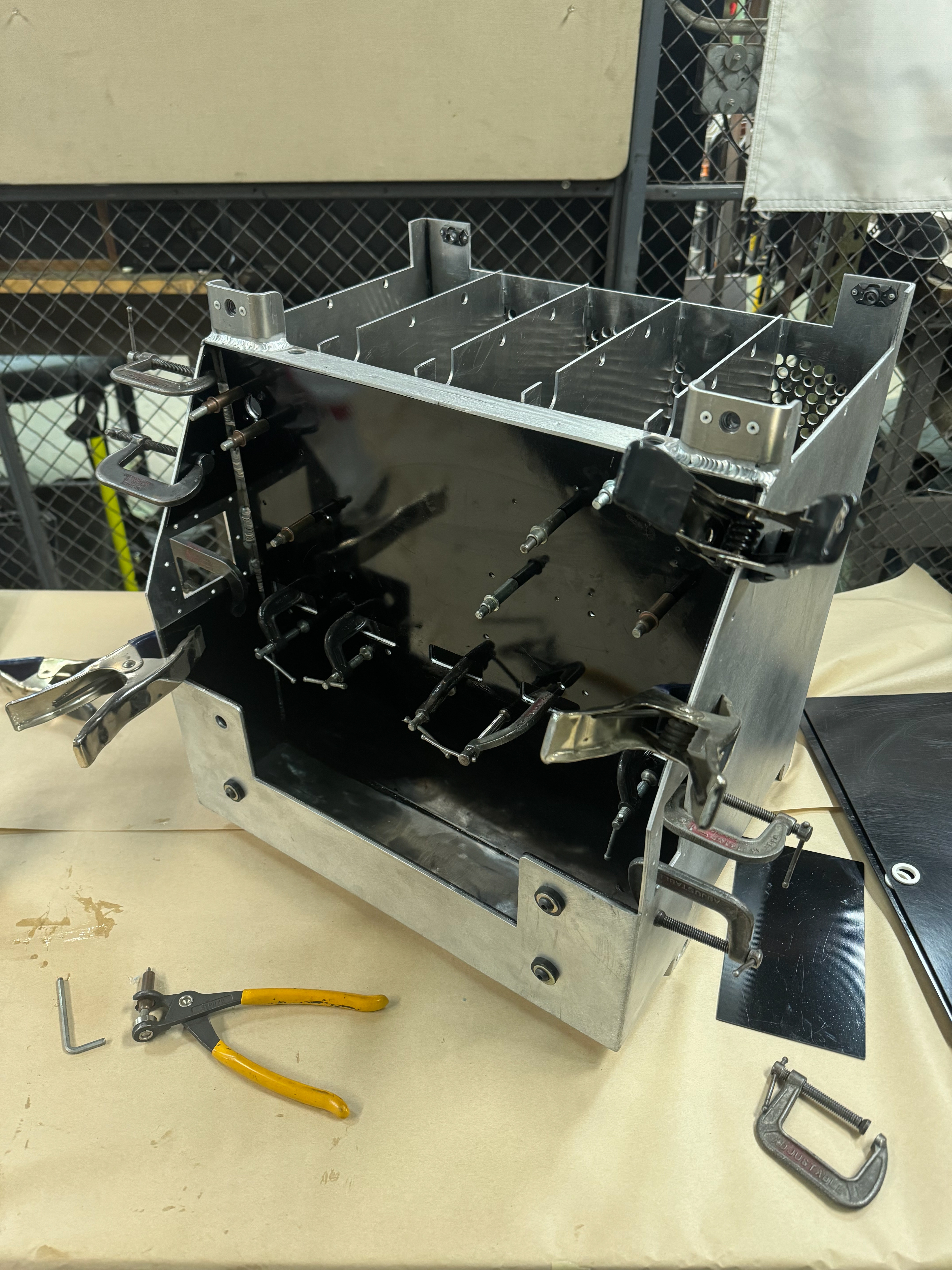

clamping G10 pieces to lid

using weights to hold flor pieces while curing

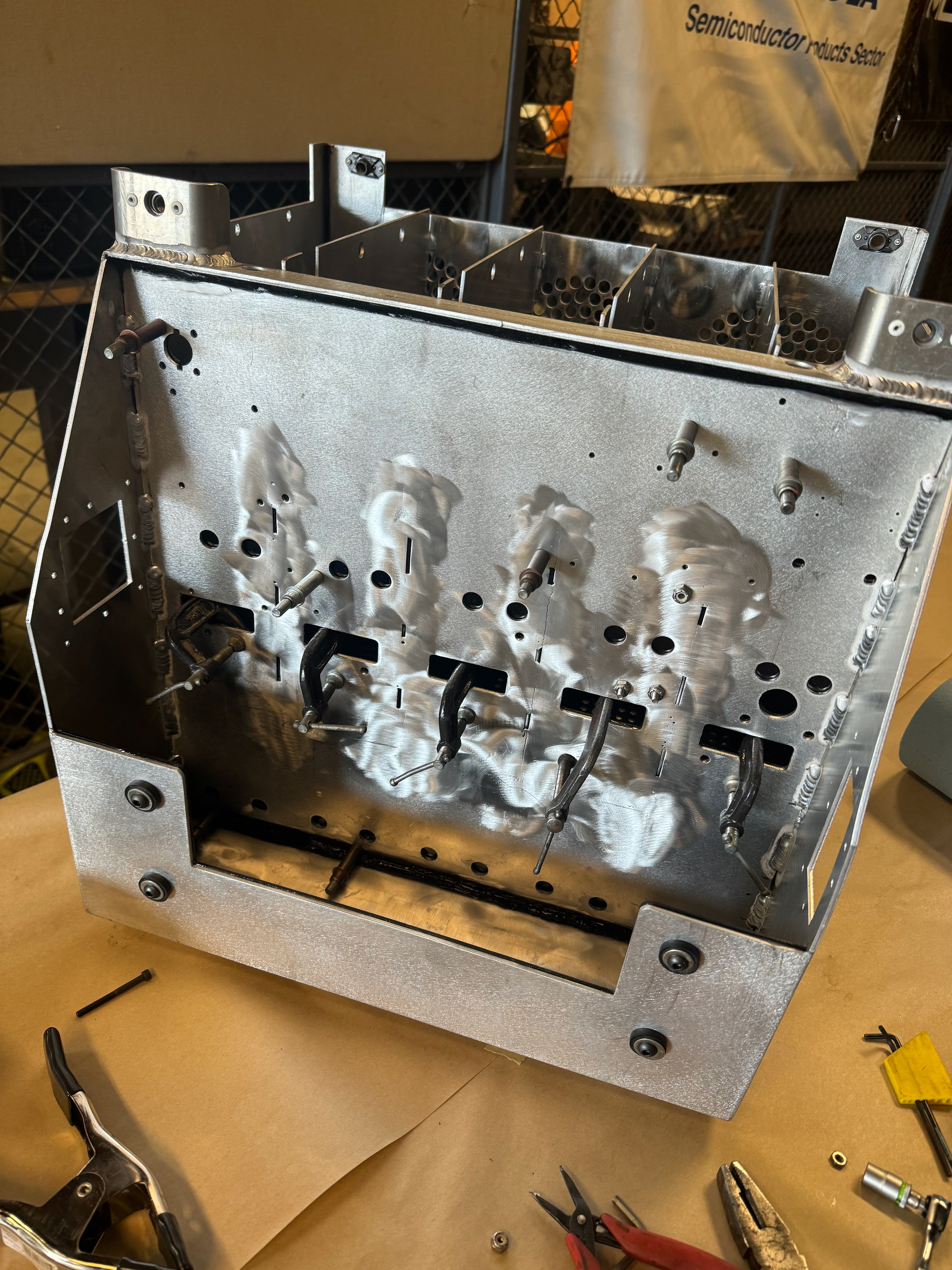

using clicos and clamps to hold segment pieces wjhile curing

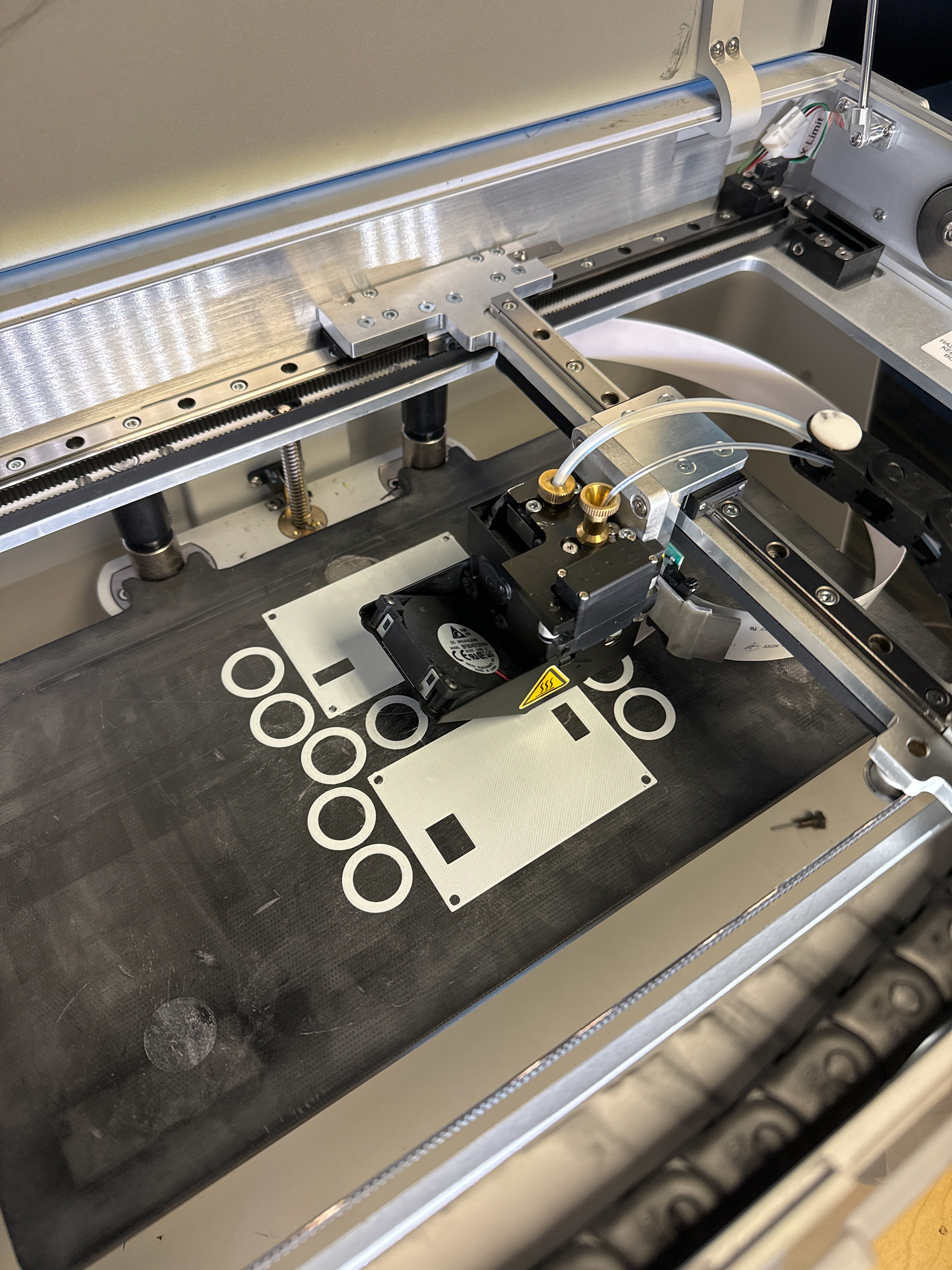

printing component boxes

epoxy-ing segment pieces with teammates

clamping the front component divider

holding the segment pieces during cure

applying kapton tape to remaining exposed metal

fitting lid and weatherstriping

apply HV safety stickers